LS & LSH SERIES Engraving machines

CUT, MARK AND ENGRAVE

Laser Cutting & Engraving Machine

Non-contact CO2 lasers engrave, cut and mark complex shapes and text with clean edges, very quickly and without producing residue. Unlike conventional engraving machines, the NEXT laser range produces smooth, clean finished cutting surfaces without burrs, eliminating the need for finishing work. With no cutting and engraving burrs to break and wear, the laser maintains a consistent level of finish and quality.

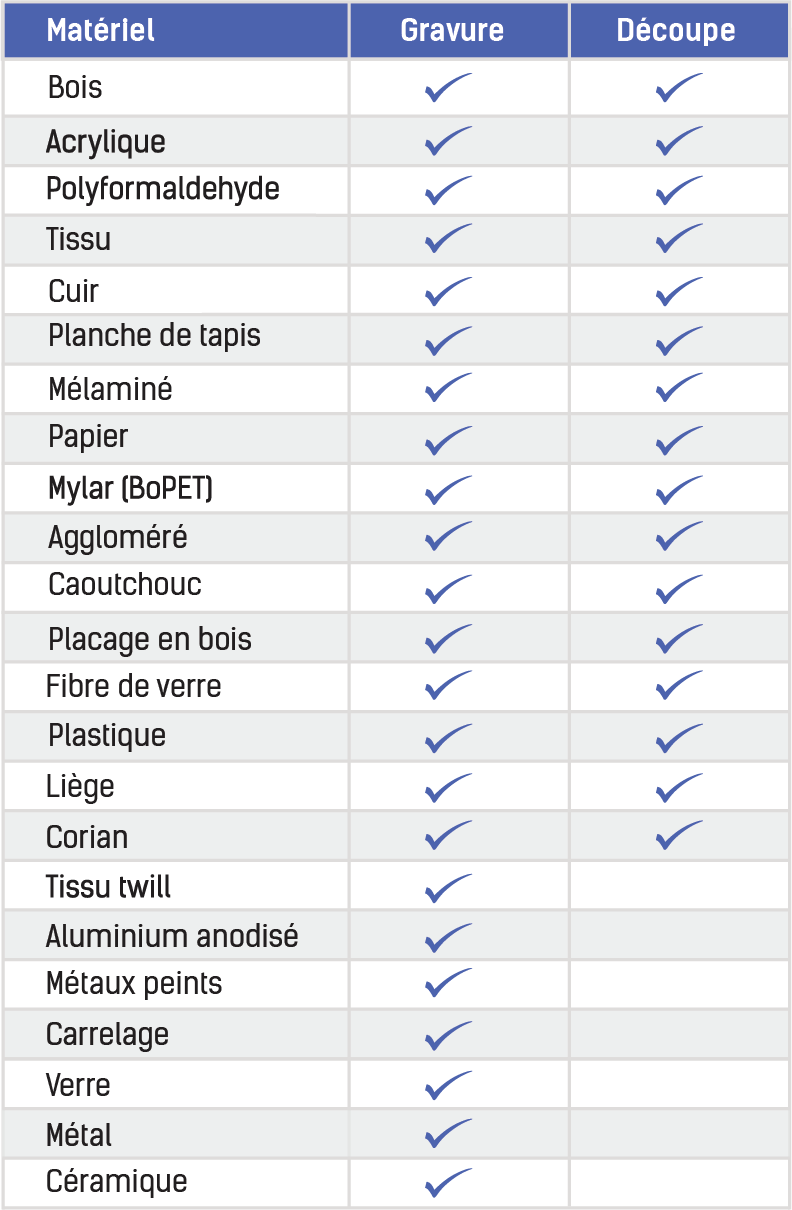

The ARIZONA range cuts, marks and engraves a large number of materials such as:

|  |  |

|  |  |

|  |  |

Next ARIZONA LS series

LS-400:

- Working area 300 x 400 mm - CO2 laser 40 w

- Cutting up to 5 mn / Engraving up to 3 mm

- Automatic focus - height adjustment

- Laser pointer for precise XY zero point adjustment

LS-600:

- Working area 600 x 400 mm - CO2 laser 80 w

- Cutting up to 8 mn / Engraving up to 3 mm

- Automatic focus - height adjustment

- Laser pointer for precise XY zero point adjustment

Next ARIZONA LSH series

LSH-900:

- Working area 600 x 900 mm - CO2 laser 130 w

- Cutting up to 18 mn / Engraving up to 8 mm

- Automatic focus - height adjustment

- Laser pointer for precise XY zero point adjustment

- Safety locking mechanism

LSH-1300:

- Working area 1300 x 900 mm - CO2 laser 150 w

- Cutting time up to 25 mn / Grave up to 10 mm

- Automatic focus - height adjustment

- Laser pointer for precise XY zero point adjustment

- Safety locking mechanism

|  |

High Speed Rails

Precision rails ensure super-high engraving speed and super-quiet operation. No other machine can achieve such performance.

- Super strong

- Protects your cables

- Prevents accidents

Electronic control system

Ruida's electronic control system optimizes engraving and cutting and allows for to perform the work in a single pass.

Aluminum platform and honeycomb plate

The aluminum platform and its standardized positioning marks simplify repetitive repetitive tasks to achieve identical results.

The honeycomb tray allows for finer tasks by separating the media from the media and avoiding overheating of the work.

- The air hose is integrated in it

- Compact, fast, robust, reliable and state of the art technology

- Prevent the laser head from shaking